Explore the world of business using 3D printing ideas. Whether it’s making unique products for customers or creating eco-friendly innovations, see how creativity and advanced technology come together.

1: Customized 3D-printed Prosthetics

Idea:

Offering personalized 3D-printed prosthetics customized to individual needs and preferences. The technology allows for precise measurements and customization, providing a comfortable and unique solution for surgery.

Potential:

The market potential for customized plastic surgery is significant, given the increasing demand for personalized healthcare solutions. This caters to a niche market and encourages customer satisfaction.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $15,000 – $30,000 |

| Raw Materials | $5,000 – $8,000 |

| Software & Design | $2,000 – $5,000 |

| Marketing | $3,000 – $6,000 |

| Operating Space | $10,000 – $15,000 |

| Miscellaneous Expenses | $2,000 – $4,000 |

Key Risks:

- Technological failure leads to product defects.

- Intensive competition from traditional prosthetic providers.

- Developing regulatory landscape.

Existing Businesses:

“XYZ Prosthetics” and “InnoLimbs” have successfully implemented this model.

Steps to Start:

- Acquire 3D printing expertise or hire skilled professionals.

- Establish partnerships with healthcare professionals.

- Develop a user-friendly online platform for orders and customization.

- Implement careful quality control measures.

Success Ratio:

Medium to High. Success depends on the ability to deliver high-quality, customized products and effective marketing strategies.

Estimated Time to Success:

12-18 months, considering market penetration and brand establishment.

Requirements:

- Proficiency in 3D printing technology.

- Understanding of prosthetics and healthcare regulations.

- Marketing and customer relationship management skills.

Qualifications:

Knowing engineering, prosthetics, or healthcare management is helpful.

Pro Key Tips:

- Prioritize quality control to build trust.

- Collaborate with healthcare professionals for confirmations.

- Regularly update product designs to stay competitive.

2: 3D-Printed Home Decor

Idea:

Creating a business that offers customizable 3D-printed home decor items, such as lampshades, flowerpots, and wall art, providing customers with unique and personalized interior design solutions.

Potential:

The home decor market has a broad consumer base, and personalized items are gaining popularity.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $10,000 – $20,000 |

| Design Software | $2,000 – $4,000 |

| Marketing | $3,000 – $5,000 |

| Raw Materials | $5,000 – $8,000 |

| Website Development | $2,000 – $5,000 |

| Packaging | $1,000 – $3,000 |

Key Risks:

- Rapid design replication by competitors.

- Fluctuating consumer preferences in home decor.

- Shipping and logistics challenges.

Existing Businesses:

“Elegance in Print” and “CustomDeco” have successfully implemented this model.

Steps to Start:

- Build a diverse and appealing product portfolio.

- Develop an engaging e-commerce website for customer orders.

- Establish partnerships with interior designers for collaboration.

- Invest in visually appealing packaging for a premium feel.

Success Ratio:

Medium. Success depends on staying ahead in design trends and effective marketing.

Estimated Time to Success:

6-12 months, considering product development and brand recognition.

Requirements:

- Creative design skills or collaboration with designers.

- Understanding of e-commerce platforms.

- Marketing and branding expertise.

Qualifications:

Having experience in design, interior decorating, or business management is helpful.

Pro Key Tips:

- Regularly update product designs to align with market trends.

- Offer limited edition or seasonal collections.

- Utilize social media for visual marketing.

3: 3D-Printed Educational Models

Idea:

Providing 3D-printed educational models for schools and colleges, catering to various subjects such as biology, geography, and history. This business aims to enhance the learning experience through physical and interactive models.

Potential:

The educational sector is continually seeking innovative teaching aids. 3D-printed models offer a hands-on learning experience, making complex concepts more available.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $12,000 – $25,000 |

| Educational Expertise | $5,000 – $10,000 |

| Marketing | $3,000 – $6,000 |

| Raw Materials | $6,000 – $9,000 |

| Distribution | $4,000 – $7,000 |

| Website Development | $2,000 – $4,000 |

Key Risks:

- Adapting to changing educational curricula.

- Gaining approvals from educational boards.

- Managing inventory effectively.

Existing Businesses:

“EduPrint Models” and “Learn3D Concepts” have successfully implemented this model.

Steps to Start:

- Collaborate with educators to identify in-demand models.

- Establish partnerships with educational institutions.

- Provide training for educators on integrating 3D models into the curriculum.

Success Ratio:

Medium to High. Success depends on understanding educational needs and effective collaboration.

Estimated Time to Success:

12-24 months, considering educational partnerships and market penetration.

Requirements:

- Understanding of educational needs.

- Collaboration skills with educators and schools.

- Marketing and distribution expertise.

Qualifications:

Having experience in education, 3D printing, or business management can be helpful.

Pro Key Tips:

- Stay updated with educational trends and curricula.

- Offer customization for specific educational requirements.

- Provide teacher training programs for effective use of the models in classrooms.

4: 3D-Printed Custom Footwear

Idea:

Initiate a business that makes customized, 3D-printed footwear. Utilize the latest technology to scan customers’ feet for precise measurements, offering comfortable and stylish shoes tailored to individual preferences.

Potential:

The market for specially made fashion items is on the rise. Personalized footwear addresses both comfort and style preferences, providing a niche audience.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $20,000 – $40,000 |

| Foot Scanning Devices | $5,000 – $8,000 |

| Design Software | $2,000 – $5,000 |

| Raw Materials | $8,000 – $12,000 |

| Marketing | $4,000 – $7,000 |

| Retail Space (if any) | $15,000 – $25,000 |

Key Risks:

- Fashion trends quickly evolving.

- Ensuring comfort and durability of 3D-printed materials.

- Initial skepticism regarding 3D-printed fashion.

Existing Businesses:

“SoleCraft” and “FootPrint Couture” have successfully embraced this business model.

Steps to Start:

- Invest in state-of-the-art foot scanning technology.

- Collaborate with fashion designers for diverse styles.

- Create an engaging online platform for orders.

- Establish partnerships with fashion influencers for promotion.

Success Ratio:

Medium to High. Success hinges on staying ahead of fashion trends and marketing strategies.

Estimated Time to Success:

12-18 months, considering brand establishment and market penetration.

Requirements:

- Collaboration with fashion designers.

- Knowledge of 3D printing technology.

- Marketing and branding expertise.

Qualifications:

A background in fashion, 3D printing, or retail management is advantageous.

Pro Key Tips:

- Regularly update shoe designs to align with fashion trends.

- Highlight the comfort and durability of 3D-printed footwear.

- Advantage social media influencers for marketing.

5: 3D-Printed Pet Products

Idea:

Establishing a business that offers personalized and 3D-printed pet products, including customized pet bowls, toys, and even pet accessories. Supply to the growing demand for unique and high-quality pet merchandise.

Potential:

The pet industry is booming, and pet owners increasingly seek unique and customized products. 3D printing allows for intricate designs and tailored solutions.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $15,000 – $25,000 |

| Design Software | $3,000 – $6,000 |

| Raw Materials | $6,000 – $10,000 |

| Marketing | $3,000 – $5,000 |

| E-commerce Platform | $2,000 – $4,000 |

| Packaging | $1,000 – $3,000 |

Key Risks:

- Competing with established pet product brands.

- Ensuring products are pet-safe and durable.

- Addressing diverse pet owner preferences.

Existing Businesses:

“PawPrint Creations” and “PetCraft Designs” have successfully ventured into this market.

Steps to Start:

- Research and design pet-friendly 3D-printed materials.

- Create an online store for easy customer access.

- Collaborate with pet influencers for marketing.

- Consider eco-friendly packaging for sustainability.

Success Ratio:

Medium. Success depends on product uniqueness and effective marketing strategies.

Estimated Time to Success:

9-15 months, considering brand recognition and market penetration.

Requirements:

- Understanding of pet safety standards.

- Creative design skills or collaboration with designers.

- E-commerce and marketing expertise.

Qualifications:

A pet care, design, or business management background is advantageous.

Pro Key Tips:

- Prioritize pet safety in product design.

- Utilize social media for pet influencer partnerships.

- Offer customizable options for diverse pet preferences.

6: 3D-Printed Architectural Models

Idea:

Starting a business that specializes in creating detailed and customized 3D-printed architectural models for architects, real estate professionals, and students. Providing accurate representations of buildings, landscapes, and urban planning projects.

Potential:

The demand for realistic architectural models is high in the fields of architecture, real estate, and urban planning. 3D printing enables precise detailing and customization.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $25,000 – $40,000 |

| Design Software | $4,000 – $8,000 |

| Raw Materials | $10,000 – $15,000 |

| Marketing | $3,000 – $6,000 |

| Website Development | $2,000 – $5,000 |

| Collaboration Tools | $2,000 – $4,000 |

Key Risks:

- Accuracy and precision in model creation.

- Niche market with specialized demands.

- Managing large-scale projects efficiently.

Existing Businesses:

“Architect Print Models” and “UrbanCraft Creations” have successfully embraced this business model.

Steps to Start:

- Invest in high-quality 3D printing technology.

- Collaborate with architectural firms for project partnerships.

- Develop a user-friendly online platform for project inquiries.

- Employ skilled model designers for accuracy.

Success Ratio:

Medium to High. Success depends on precision, accuracy, and establishing partnerships with architectural firms.

Estimated Time to Success:

18-24 months, considering project cycles and market penetration.

Requirements:

- Understanding of architectural design principles.

- Collaboration with architects and real estate professionals.

- Marketing and project management skills.

Qualifications:

Having experience in architecture, 3D modeling, or project management is helpful.

Pro Key Tips:

- Showcase previous projects in a portfolio for credibility.

- Invest in high-quality materials for realistic models.

- Establish partnerships with architectural firms for a steady project flow.

7: 3D-Printed Planters and Garden Decor

Idea:

Introduce a business focused on creating 3D-printed planters, garden ornaments, and outdoor decor items. The customization aspect allows customers to design unique pieces that complement their outdoor spaces.

Potential:

With the increasing popularity of gardening and outdoor living, personalized garden decor items provide a niche yet growing market. 3D printing allows for complicated designs that traditional methods may struggle to achieve.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $15,000 – $25,000 |

| Design Software | $3,000 – $6,000 |

| Raw Materials | $7,000 – $12,000 |

| Marketing | $4,000 – $7,000 |

| E-commerce Platform | $2,000 – $5,000 |

| Packaging | $1,000 – $3,000 |

Key Risks:

- Seasonal demand variations.

- Ensuring durability for outdoor use.

- Competition with traditional garden decor suppliers.

Existing Businesses:

“NatureCraft Creations” and “GardenPrint Designs” have successfully implemented this business model.

Steps to Start:

- Create a diverse range of garden decor items.

- Establish an easy-to-navigate online store.

- Collaborate with gardening influencers for promotion.

- Ensure materials withstand outdoor conditions.

Success Ratio:

Medium to High. Success relies on unique designs, durability, and effective marketing.

Estimated Time to Success:

12-18 months, factoring in brand recognition and market penetration.

Requirements:

- Creative design skills or collaboration with designers.

- Understanding of outdoor material durability.

- Marketing and e-commerce expertise.

Qualifications:

Knowing about design, gardening, or managing businesses can be helpful.

Pro Key Tips:

- Leverage social media for garden influencer partnerships.

- Highlight the durability and weather resistance of the products.

- Offer seasonal or themed collections.

8: 3D-Printed Custom Board Games

Idea:

Create a business that offers personalized and 3D-printed custom board games. Customers can design their game boards, pieces, and rules, providing a unique and engaging gaming experience.

Potential:

The board game industry is experiencing a resurgence, and personalized gaming experiences are highly sought after. 3D printing allows for intricate and customized game components.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $20,000 – $35,000 |

| Design Software | $4,000 – $7,000 |

| Raw Materials | $8,000 – $15,000 |

| Marketing | $5,000 – $8,000 |

| E-commerce Platform | $3,000 – $6,000 |

| Quality Control | $2,000 – $4,000 |

Key Risks:

- Competition with traditional board game manufacturers.

- Balancing customization with game playability.

- Establishing a niche within the gaming community.

Existing Businesses:

“CustomGameWorks” and “PlayPrint Innovations” have successfully embraced this business model.

Steps to Start:

- Develop a user-friendly online platform for game customization.

- Collaborate with board game fans for feedback.

- Implement exact quality control measures.

- Engage in partnerships with gaming cafes and stores.

Success Ratio:

Medium. Success joints on unique game concepts, playability, and effective marketing.

Estimated Time to Success:

15-24 months, considering brand recognition and market penetration.

Requirements:

- Creative design skills or collaboration with game designers.

- Understanding of game mechanics and playability.

- Marketing and e-commerce expertise.

Qualifications:

Having experience in design, gardening, or business management can be helpful.

Pro Key Tips:

- Foster a community around your custom games.

- Regularly release new game concepts to keep interest high.

- Offer limited edition or themed game sets.

9: 3D-Printed Musical Instruments and Accessories

Idea:

Establish a business focused on creating 3D-printed musical instruments and accessories, such as custom guitar bodies, unique wind instrument designs, and personalized drum accessories.

Potential:

Musicians often seek instruments that reflect their style and preferences. 3D printing allows for the creation of customized and visually striking musical equipment.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $25,000 – $40,000 |

| Design Software | $5,000 – $8,000 |

| Raw Materials | $10,000 – $18,000 |

| Marketing | $4,000 – $7,000 |

| Quality Control | $3,000 – $6,000 |

| Collaboration with Musicians | $5,000 – $10,000 |

Key Risks:

- Ensuring structural integrity and sound quality.

- Competition with traditional instrument manufacturers.

- Building collaborations with musicians.

Existing Businesses:

“SoundPrint Innovations” and “CustomTune Instruments” have successfully ventured into this market.

Steps to Start:

- Collaborate with musicians for design feedback.

- Invest in acoustic testing for instrument quality.

- Develop an online platform for easy customization and orders.

- Engage in partnerships with music schools and bands.

Success Ratio:

Medium to High. Success depends on unique designs, sound quality, and effective marketing.

Estimated Time to Success:

18-24 months, considering brand establishment and market penetration.

Requirements:

- Collaboration with musicians and music experts.

- Understanding of instrument design and acoustics.

- Marketing and e-commerce expertise.

Qualifications:

Having experience in music, designing instruments, or managing businesses can be helpful.

Pro Key Tips:

- Highlight collaborations with well-known musicians.

- Underline the quality of sound and materials in marketing.

- Offer limited edition or artist-inspired instrument designs.

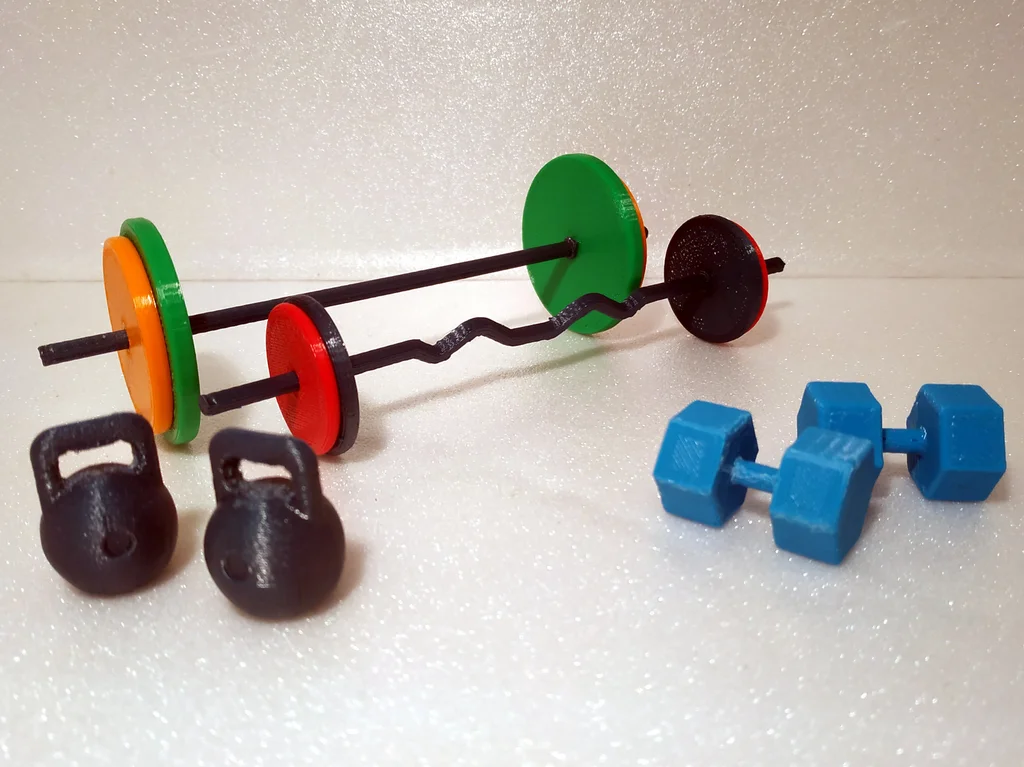

10: 3D-Printed Fitness Equipment

Idea:

Introduce a business that focuses on creating traditional 3D-printed fitness equipment, such as dumbbells, resistance bands, and unique workout tools. Offer customers the ability to design equipment that suits their specific fitness needs and preferences.

Potential:

The fitness industry is ever-growing, and personalized workout equipment can satisfy to individuals with specific fitness goals and preferences. 3D printing allows for innovative and user-friendly designs.

Cost Estimate:

| Cost Category | Estimated Cost (USD) |

| 3D Printers | $20,000 – $35,000 |

| Design Software | $3,000 – $6,000 |

| Raw Materials | $8,000 – $15,000 |

| Marketing | $4,000 – $7,000 |

| E-commerce Platform | $3,000 – $6,000 |

| Quality Control | $2,000 – $4,000 |

Key Risks:

- Ensuring durability and safety of 3D-printed materials.

- Competition with traditional fitness equipment manufacturers.

- Adjusting to developing fitness trends.

Existing Businesses:

“FitPrint Innovations” and “CustomFit Gear” have successfully embraced this business model.

Steps to Start:

- Collaborate with fitness professionals for design input.

- Conduct thorough testing for equipment safety and durability.

- Develop an online platform for easy customization and orders.

- Engage in partnerships with fitness influencers for promotion.

Success Ratio:

Medium to High. Success depends on meeting safety standards, unique designs, and effective marketing.

Estimated Time to Success:

15-24 months, considering brand recognition and market penetration.

Requirements:

- Collaboration with fitness professionals.

- Understanding of fitness equipment safety standards.

- Marketing and e-commerce expertise.

Qualifications:

A fitness, product design, or business management background is advantageous.

Pro Key Tips:

- Emphasize the safety and durability of 3D-printed fitness equipment.

- Collaborate with fitness influencers for product endorsements.

- Stay informed about the latest fitness trends for product innovation.